ROOF TRUSS DESIGN: A PROFESSIONAL'S GUIDE

Discover the intricacies of roof truss design in our professional's guide, covering everything from basic types to complex applications in construction.

Are you building an extension, new house or larger commercial developments? Hopefully this guide we’ve put together will give you more of an insight in to the Roof Truss market.

What is a Roof Truss?

Roof Trusses are timber frames that are fastened together using gang nails, bolts or pegs to form a structurally sound component that will form part of the roof. They are used in place of traditional timbers where a joiner would need to form the roof himself on site. We’ll take a look at the pros and cons of both later.

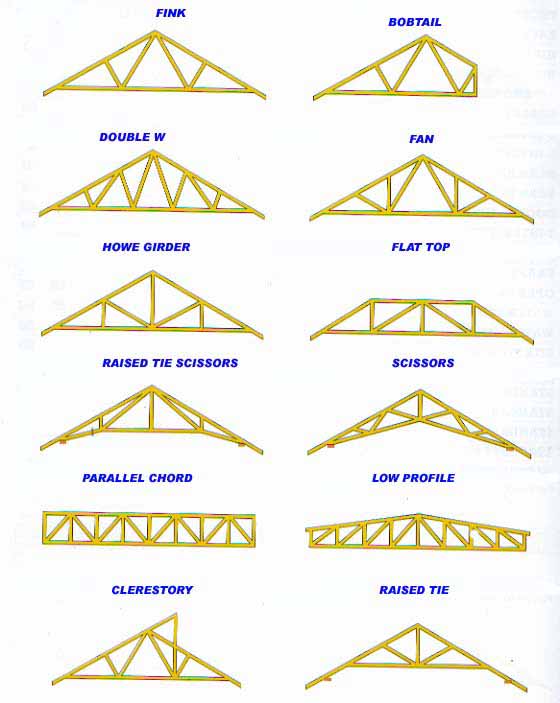

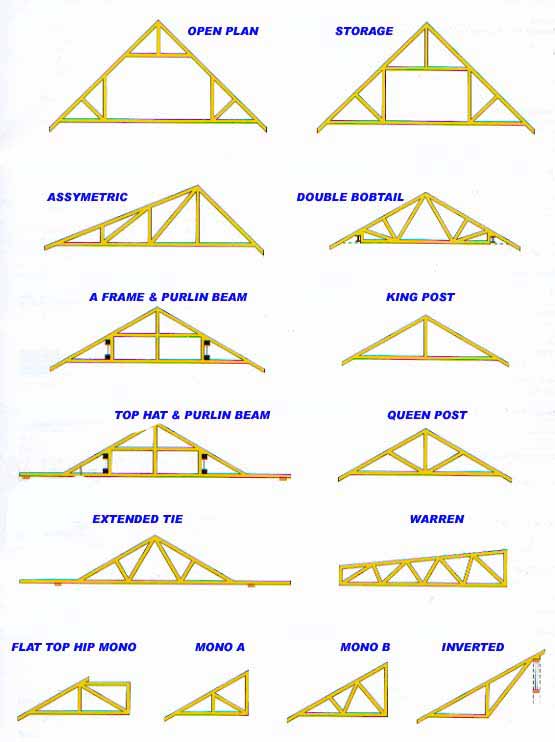

Types of truss available

Roof trusses, or trussed rafters as they are sometimes known come in many different forms. The Two most popular types being the most commonly used ‘Fink’ truss and where customers require living space in the roof ‘Attic’ trusses are used. These are also known as ‘room in the roof’ trusses. Other popular truss types are:

• Cantilever – the horizontal element which forms the ceiling part extends out past the point of loading. This gives an extended overhang which in all intents and purposes forms a sheltered area.

• Bobtail – also known as a ‘stubbed end’ truss. As the name suggests, one or both sides of a standard fink type truss are cut back on one or both sides.

• Queen Post – these are the more traditional types of trusses that you would generally find in older buildings and barns

• Raised Tie – feature an extended/flying rafter leg from where the truss would usually bare on to the wall plate

• Scissor – used where a sloped ceiling is required

Please see the illustrations below which will show these truss types plus some of the less popular ones available.

All trusses can be supplier untreated or pre-treated to stop rot and insect attack.

Design

All roof trusses are designed by companies that have purpose built software to calculate the weight of the roof covering i.e. roof tiles and roof slates. This is known as the ‘dead load’. They will also take in to account the local wind factor and local snow factor. An allowance for safety will also be factored in.

It’s amazing what can be designed for roofs these days as bespoke trusses up to 20 metres in span can be manufactured for the larger scale jobs. This is coupled with almost endless possibilities. It’s very rare these days that the carpenter has to get his saw, hammer and nails out!

Once the trusses have been supplied to a job, full structural calculations, if required by the local building control department can be provided on request. Any reputable company will have accreditation from TRADA or similar companies.

Taking measurements

This is the most important thing to get right when looking at ordering roof trusses. A few inches out one way or another and you can find yourself with an expensive pile of fire wood! The critical measurement to get right is the span or ‘over wall plate measurement’. Things such as the pitch of the roof on new build jobs will generally be pre-determined on the plans. Sometimes on extensions it may be necessary to take height measurements if matching up to existing roofs.

If you are worried about having to take these measurements yourself, there is usually help on hand. Most truss manufacturing companies will offer a free measuring service. This will sometimes be subject to them receiving an order. Orders can be placed based on the measurements taking from full working drawings. In most instances, these should be fairly close to the actual measurements on site.

If you need further help we can be contacted by email or by phone on 01274 602367 where we’ll be happy to offer advice on this matter.

Pros and cons

There aren’t really many cons. The main one if using the more standard type fink trusses and similar would be the lack of usable attic space. If using heavier attic type trusses, it will generally be necessary to have a crane on site to lift them in to place therefore adding to the cost.

The initial cost of buying trusses compared to loose timbers will always be higher. The cost of building the roof though will be considerably less than a carpenter building a roof from loose timbers.

The pros are numerous. The main ones being that they are fast to install, requires no specialist tools or skills, less expensive than a traditional roof overall. As they are an engineered product there is also very little on-site waste which is also better for the environment.

Can I alter the trusses on my property?

The short answer would be NO! As the trusses have been designed as a complete entity, the last thing you want to do is start cutting away at bits of the roof you may think aren’t important. They are there for a reason.

However it is possible to alter the trussed roofs and they can even be adapted to form habitable spaces. This is a big job though that will need the addition of steel beams. It must be stressed though that a structural engineer must be consulted to come up with a design before commencing any such work.